With the considerable improvements in storage capabilities, there is no reason why one would prefer a Hard Disk Drive over a Solid State Drive. Both these are non-volatile storage devices, which means the data written to them will not disappear even if the power is shut. While their purpose is the same, their construction differs due to which the performance and storage capabilities. A hard disk drive (HDD) stores information on a rotating disk using a magnetic arm and hence is noisy, less efficient and more power consuming. Learn more about HDDs here.

Solid State Drives (SSDs)

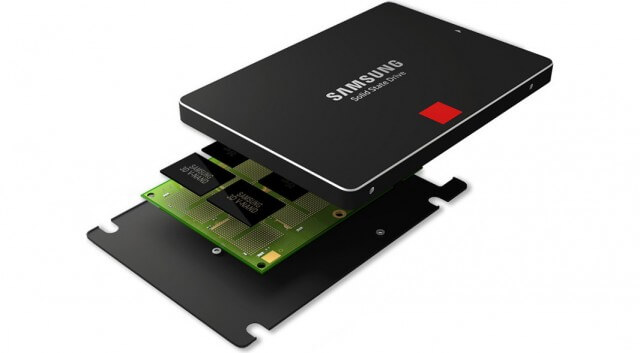

A SSD instead stores data in flash memory chips which are interconnected thus retaining huge amount of data. Though a little costlier than the HDDs, these SSDs are fast becoming the preferred choice of storage devices in desktops and laptops.

In this mix, Samsung pops out the SSD 850 PRO which features the 32-layer 3D V-NAND Flash Memory. This is an improvement over the earlier models of SSDs which were based on the 2D Planar NAND technology; the result is more storage, more speed, more efficiency and hence more reliability.

2D Planar NAND and 3D Vertical NAND – The Difference

Instead of using the conductive floating gate (like all the other flash memory chips) to store charge, the 3D V-NAND Technology uses Silicon Nitride (an insulator) to store charge by means of the Charge Trap Flash (CTF) technology. This little modification means that there is no memory wear (or) flash wear caused due to short circuit currents.

But the operation of a control gate MOSFET can explained practically considering a bucket of water. The water stays in the bucket until there isn’t any hole in the bucket. Once there is a hole, sooner or later the entire bucket is gets emptied. Here water is analogy to the charge present on the floating gate and the bucket that holds this water is analogous to the layer of insulating material around the floating gate.

This hole formation in the insulating oxide layer is the resultant of the stress caused on this layer while writing into the drive. Due to which over a span of time the degradation is multiplied and ultimately the floating gate gets short-circuited. Manufacturers, in order to avoid such floating gate collapses, usually thicken this insulating layer thus increasing the ‘endurance’, hence the life time of a typical 2D Planar NAND SSDs.

But a Charge Trap Flash (CTF) technology, in 3D Vertical NAND is immune to such memory wear outs and a short circuit will result in no severe effects. This is primarily because the charge is stored on an insulator and no short-circuit would disturb this charge. Hence there is no need to employ a thick oxide layer and the capacitance effect can be kept to minimum levels, thus, improving the speed of the write and read operations and the interference with neighboring cells isn’t much of a problem.

It is due to this vital aspect that a charge trapping cell can be stacked over another such cell and this is why 24 layer 3D V-NAND and a 32 layer 3D V-NAND were a reality.

The Plus Points:

The vertical stacking of cells is more advantageous than the planar arrangement. With vertical stacking, a higher capacity of cells can be included in a given volume. This improves the electrical efficiency as the connections are shortened hence much lower power is consumed. Thanks to the charge trap flash technology due to which Samsung has openly announced a warranty period of 10 years on the SSD 850 PRO and that’s how confident they are about the endurance of the 3D V-NAND. Hence the Samsung 850 PRO SSD will surely turn out to be a revolutionary storage device once it is set into the market.